User Focus: Australian Diamond Company

History of ADC

The Australian Diamond Company (ADC) was founded in 1982 and first opened it’s doors on Swanston Street in the heart of Melbourne’s vibrant CBD. Throughout ADC’s history, the company has built a shining reputation for its excellence in craftsmanship and inimitable design.

Today, more than 3 decades later, ADC continues to push boundaries of excellence in fine jewellery making traditions which excite and inspire.

ADC master jewellers collaborate with our skilled designers to create pieces that celebrate the rarity and beauty of precious gem stones. We take pride in our personalized service combined with our exquisite range of jewels to suit the most discerning of tastes. Enjoying success and growth over the decades sparked a re-location of the showroom. In 2014, the ADC doors opened in the Centrepoint Arcade nestled in Melbourne’s iconic Bourke Street Mall.

Bringing 3D printing in-house

Whilst we have an extensive range of designs on our showroom floor, many customers use these designs as their base and request changes to the design based on what they think they would like.

Historically we would record the amendments and move straight into production. Six weeks later the customer would visit to collect their item and, in some cases what the customer thought they liked turned out to be a little different. This led us to having to rework the piece to ensure the customer was 100% satisfied.

We quickly identified there was a gap in our process and explored options for solutions that would enable us to deliver a better service to customers and reduce costs from having to remake. 3D printing has been a real game changer for our business by bridging this gap and by introducing this digital process we can now deliver a finished custom design to our customer within 5-7 days.

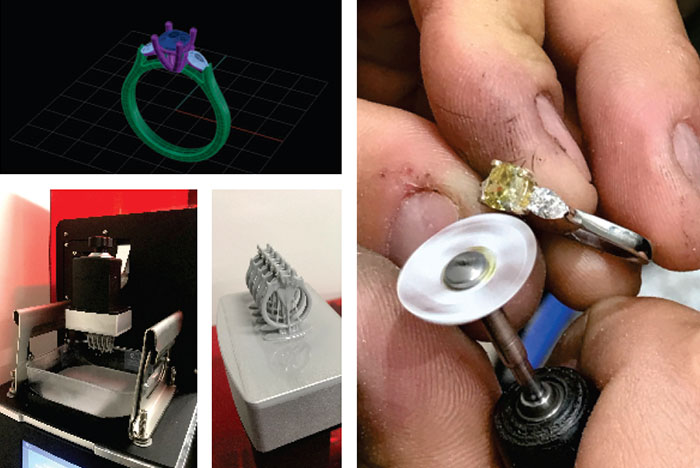

Our design & manufacture process

Our in-house design team works closely with our customers to ensure we deliver exactly what the customer wants. From initial consultation, 3D CAD design through to 3D printing and the finished piece our process is summarised in the following stages:

- Customer design meeting

- 3D CAD Design on Matrix by Gemvision

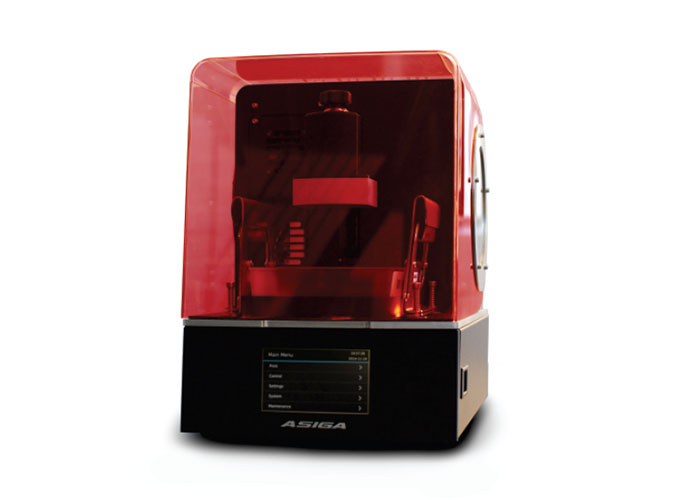

- 3D print design on the Asiga PICO2 39 in PlasGRAY (print time 50 minutes)

- Customer review meeting where they try on the 3D printed design

- Modifications if required

- 3D print in SuperCAST HD (print time from 3.5 to 8 hours depending on size/resolution)

- Cast

- Clean, polish, set stones

- Deliver to the customer

Why we purchased Asiga

Before we purchased our Asiga PICO2 39, we had a very bad experience with another 3D printer brand. We spent months trying to make this printer work and even through the manufacturer stated that it was suitable for jewellery, it wasn’t. We were then introduced to Asiga and as soon as the PICO2 39 was installed we saw immediate benefits which included quick build times, extremely high quality prints which were consistent, flexible and open to a wide range of materials and local Australian support. Asiga to those who don’t already know is an Australian company and all Asiga 3D printers are designed and manufactured in Sydney.

3D printing in-house on the PICO2 39 has enabled us to instill customer confidence, offer higher levels of customer service, improved production efficiency, reduced/removed re-working costs and ultimately achieve 100% customer satisfaction.

Written by George Bakoulas, Australian Diamond Company.

Share: