Effortless build preparation software

Powerful, smart and ready to integrate into your workflow.

Automatic object identification

The new automatic object identification tool in Composer detects object type and then automatically orients it to optimise print time and quality.

Automation is currently available for dental parts only. More industries to follow.

Work in light or dark mode.

Light or dark themes available. Set-up Composer to suit your colour preferences and define keyboard shortcuts for continuity from your CAD program.

Rapid access to 600+ materials

Stay connected to all the latest material developments and download your preferred material settings when you need them. Quick access to the Asiga Material Library direct from Composer.

Snap parts to platform

The Rotate Facet Downwards feature allows you to select a triangle on the surface you want to be snapped to the platform.

Orient parts accurately and with a single click to ensure they are attached to the platform.

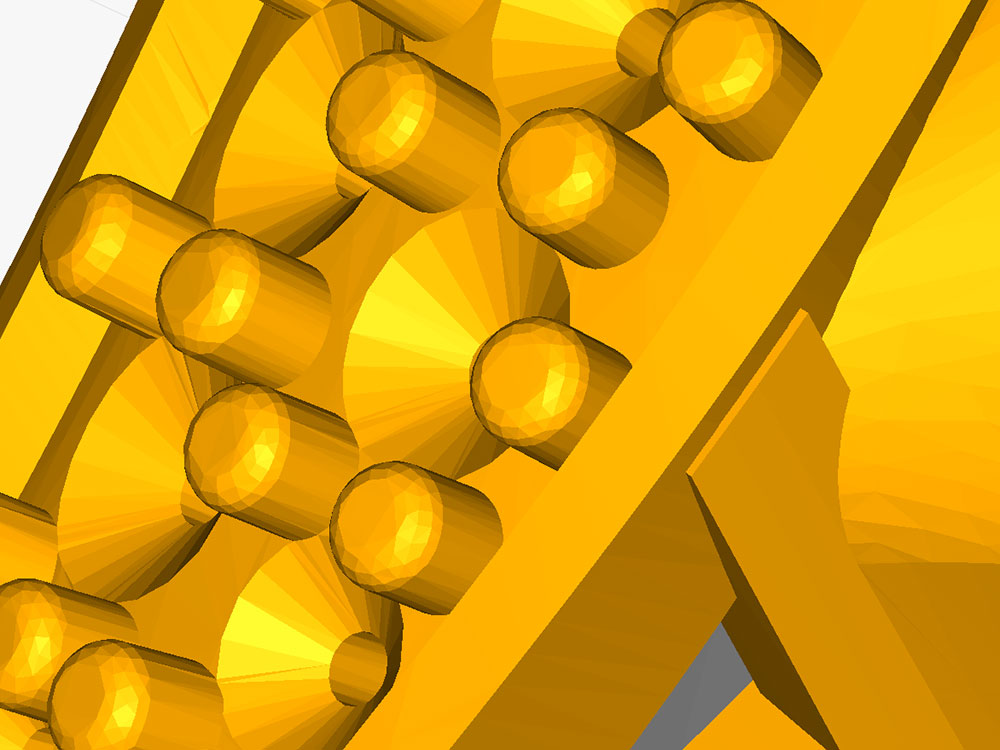

Lattice Supports. Now that’s smart!

Lattice Supports ensure all the fine details in your parts are correctly supported and protected with our geometry avoidance algorithms. Lattice Supports wrap around your parts like a safety blanket only placing support points where required.

“Composer is a powerful tool for my lab & training centre. It provides a simple interface for speed of set-up with access to all print settings for when we need them.”

Jeroen Klijnsma,

Dentiq Dental Services

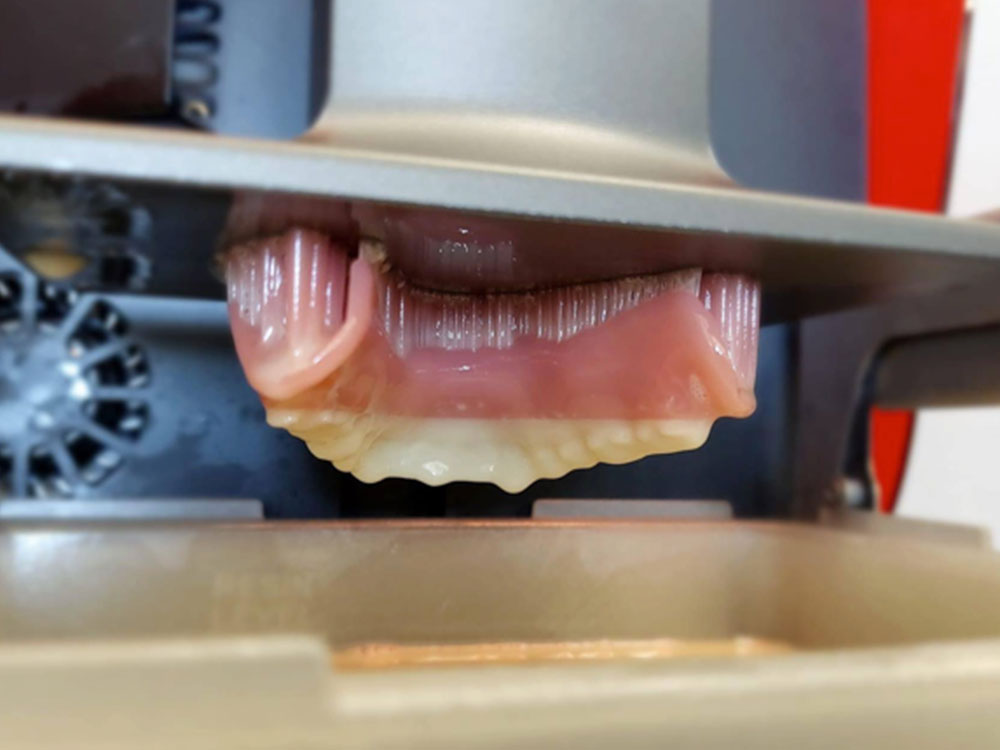

Automatic build preparation

Composer takes the guess work out of the build set-up process making sure your parts are positioned and supported correctly for every print.

Our material profiles accommodate optimised set-up preferences for all materials and geometries.

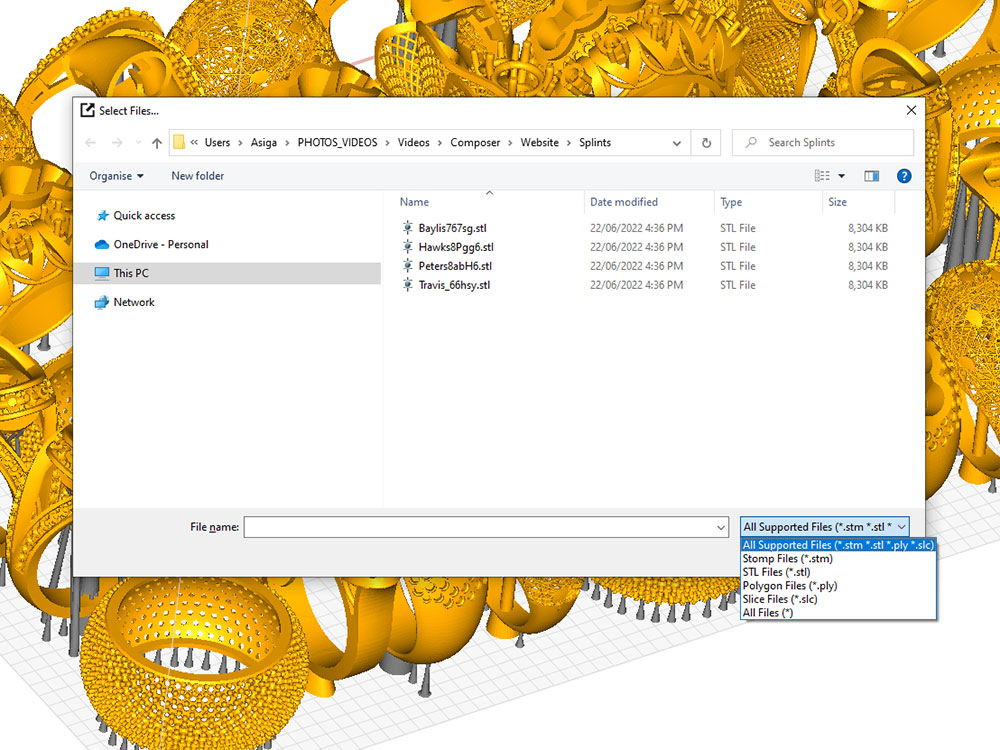

Industry-wide compatibility

A selection of file types are supported including STL, PLY, SLC and Asiga’s very own STL compression file format – STM.

Use Asiga Stomp for STL compression. It’s free.

Unrestricted print optimisation

For the advanced user looking to achieve a more finely curated output, experience unlimited access to many of the of the printer control features such as motion control, cure times, LED intensity, image optimisation and much more.

Print confidently using our default print settings or customise for your specific application.

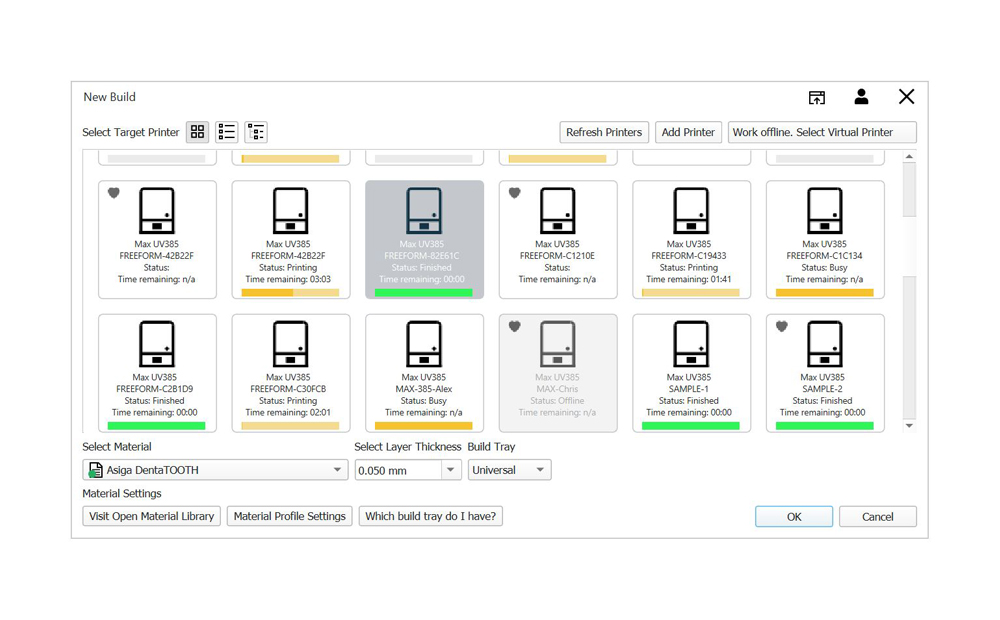

Live printer status

Keep up to date with printer status updates in real-time. Visibility of which printers are available, printing, showing a print error and completed.

“Asiga Composer provides my business a seamless connection from our design department to our production line-up of Asiga printers. Lot’s of features to choose from in a simple and intuitive interface.”

Tanya Little,

Envision Denture and Implant Centre

Maximise Z height with Multi-stacking

Multi-stacking takes full advantage of the printer Z height to increase production throughput.

Print single layers through the day and then Multi-stack for an overnight build to utilise the time when you are not in the office.

Automatic geometry repair

Composer will automatically repair files to ensure your 3D printing experience is uninterrupted. We recommend you correct errors in your design software however in some instances this can be difficult so Composer will assist and correct these for you.

Automatic repair features include mesh repair, hole filling, feature Boolean.

Print in different layer thicknesses & materials

Multi-range allows you to zip through areas of the build where resolution is less important and then slow the process down for the important, finer detailing. Set each range simply in the Advanced parameters and even switch between materials for a multi-material 3D printed part.

System requirements

Operating System

Windows

Mac

Linux

Windows

Mac

Linux

Processor:

CPU with 4 threads, 3.5 GHz

Memory:

8 GB

Graphics:

64 MB, OpenGL 2.0 or later

Mouse:

3 button with scroll wheel / trackpad