Precision 3D printed injection moulding tools

Asiga’s desktop solution takes designs to real parts in hours

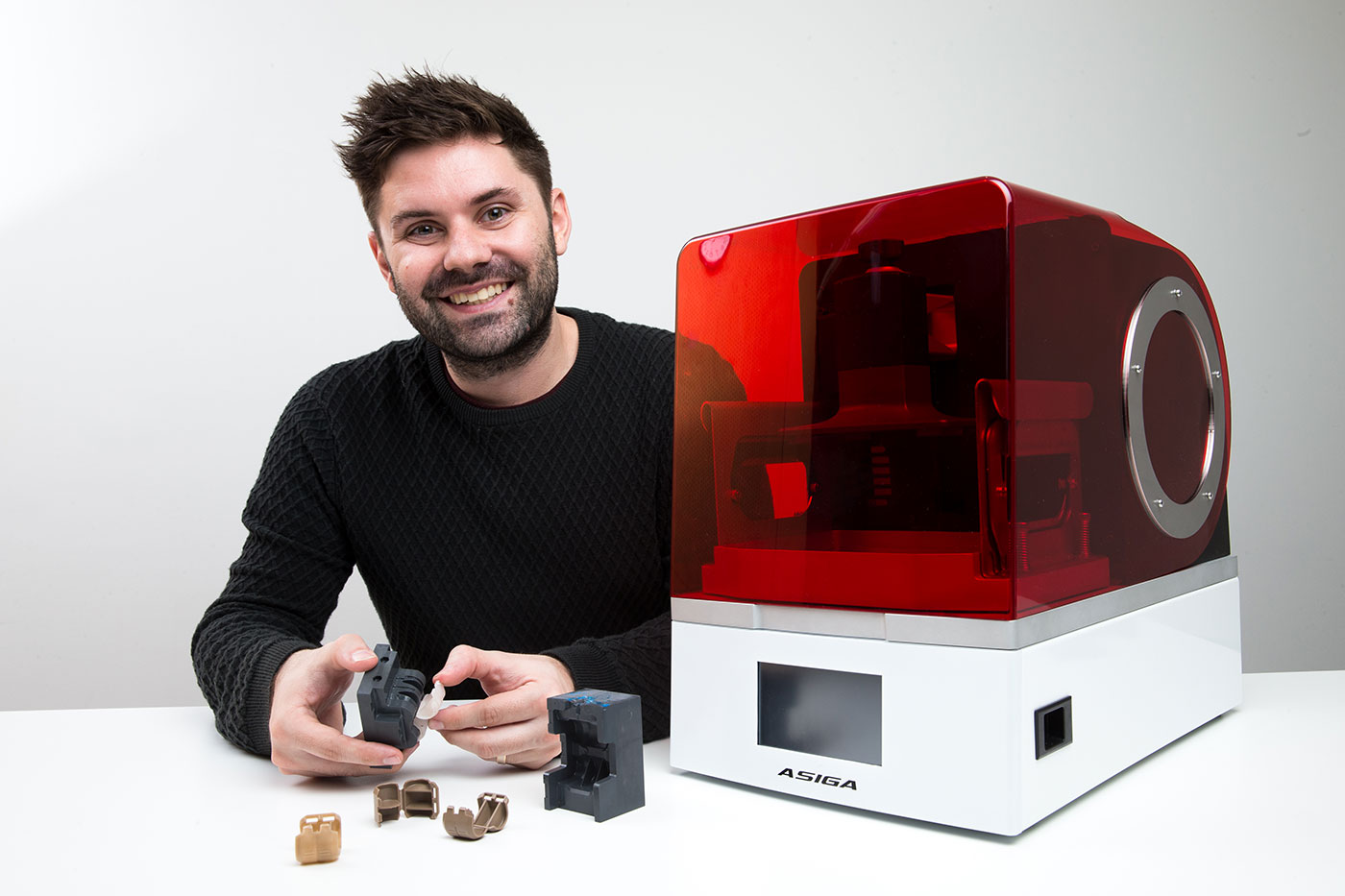

Mitchell Brown from VERT Design explains.

Our product design company was engaged to develop a variation of a hose clip that is used on a high speed production line. The product works through the use of an integral hinge and flexible clipping geometry.

Traditionally we would test the design through the used of SLS 3D printed models, however, the results achieved were not accurate. We required the geometry to be proven in the actual production materials, which in this case was injection moulded polypropylene.

Through the design phase, we developed multiple iterations. Eventually this was short-listed to two possible concepts. Producing a prototype tool in steel or aluminium would have cost many thousands of dollars and taken a minimum of 6 weeks. We turned to 3D printed tooling as it was faster and cheaper.

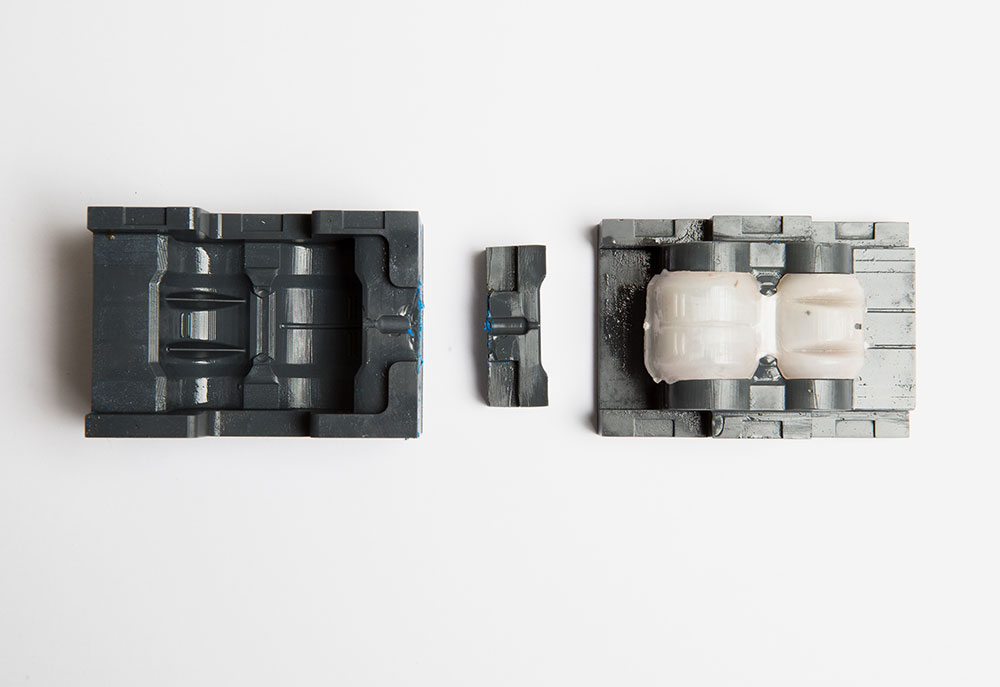

Production of the moulding tool

Behaviour of tooling whilst being run

Quality of the mouldings

Using a hand operated moulding machine we were able to produce parts of excellent quality. The surface finish achieved was similar to a fine EDM finish found in steel production tools. At times we noticed visible flow lines, voids from trapped gas, flashing and noticeable gate remains. Flashing and gate remains were trimmed by hand to clean up moulded parts. That said, it is possible to achieve cleaner parts with better process control and stable material temperature.

Condition of tooling after moulding

The FusionGRAY tooling material can wear if not treated with care. Controlled processing of the tool is necessary due to the significant hydraulic pressures involved and over-filling cavities can destroy the tool. In addition, over-clamping can also fracture weak points in the tool. In the course of cycling the tool in our project we noticed a hair-line crack form, however, this did not compromise the performance of the tool. Protection of the tool can be improved through the used of a metal bolster so that the clamping pressure is taken by the bolster rather than the 3D printed inserts.

Comparison to other 3D printers

We have previously tested digital tooling produced with other 3D printers. In my experience, FusionGRAY displays greater integral strength and produces a smoother tool surface with little to no stepped build-lines being transferred to the moulded part.

Conclusion

Share: