Programmable optical window bonding enabled 3D printing of high-resolution transparent microfluidic devices for biomedical applications

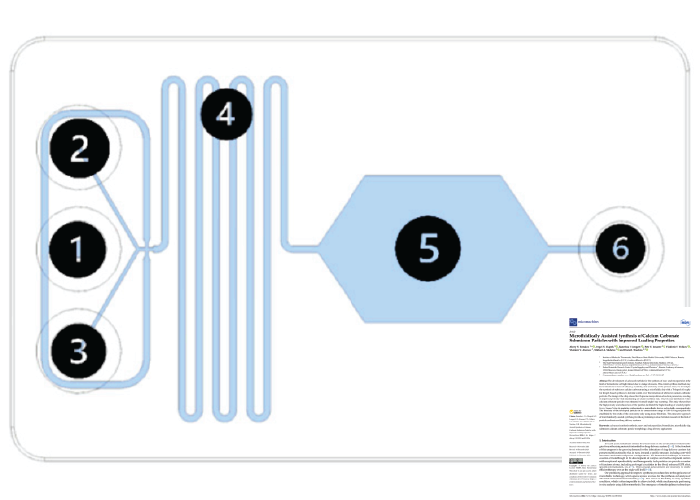

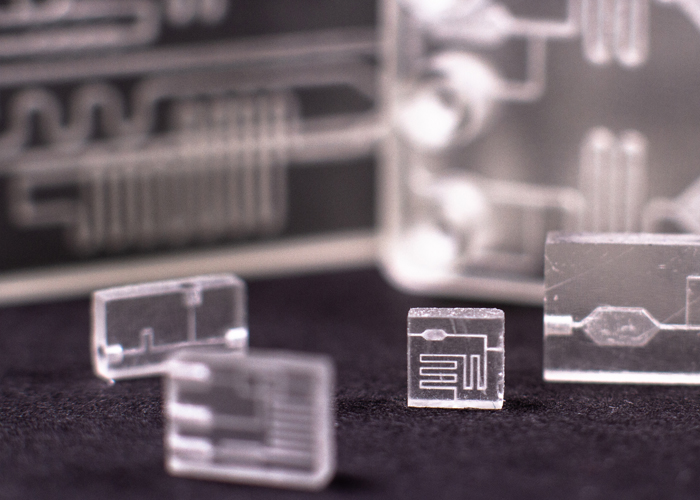

Traditional technologies for manufacturing microfluidic devices often involve the use of molds for polydimethylsiloxane (PDMS) casting generated from photolithography techniques, which are time-consuming, costly, and difficult to use in generating multi-layered structure. As an alternative, 3D printing allows rapid and cost-effective prototyping and customization of complex microfluidic structures. However, 3D-printed devices are typically opaque and are challenging to create small channels. Herein, we introduce a novel “programmable optical window bonding” 3D printing method that incorporates the bonding of an optical window during the printing process, facilitating the fabrication of transparent microfluidic devices with high printing fidelity. Our approach allows direct and rapid manufacturing of complex microfluidic structure without the use of molds for PDMS casting. We successfully demonstrated the applications of this method by fabricating a variety of microfluidic devices, including perfusable chips for cell culture, microwell scaffold for spheroid formation, and high-resolution droplet microfluidic devices involving different channel width and height for rapid antibiotic susceptibility testing. Overall, our 3D printing method demonstrates a rapid and cost-effective approach for manufacturing microfluidic devices, particularly in the biomedical field, where rapid prototyping and high-quality optical analysis are crucial.

About the Authors

Dr. Michael Chen is a Professor, Chair of Therapeutic Engineering, in the School of Engineering at The University of Edinburgh. His research is focused on biomaterials, biomedical engineering, biophysics, and the application of nanomaterials in biology and medicine. In these areas, he has been working on physical (microneedle & nanoneedle arrays) and chemical (nanomaterials) for drug delivery and sensing, as well as microfluidic devices for biomedical applications.

Dr. Mengguang Ye is a highly accomplished researcher and innovator in 3D printing, microfluidics, and biomedical engineering, with a proven track record of translating advanced scientific concepts into practical solutions. He is currently a Postdoctoral Research Associate at the University of Edinburgh, working under the supervision of Prof. Michael Chen. Mengguang holds both a PhD in Biomedical Engineering and a BEng in Chemical Engineering from the University of Edinburgh, where his work has focused on developing rapid and cost-effective methods for prototyping microdevices in biomedical applications.

Share: