From ancient techniques to digital perfection

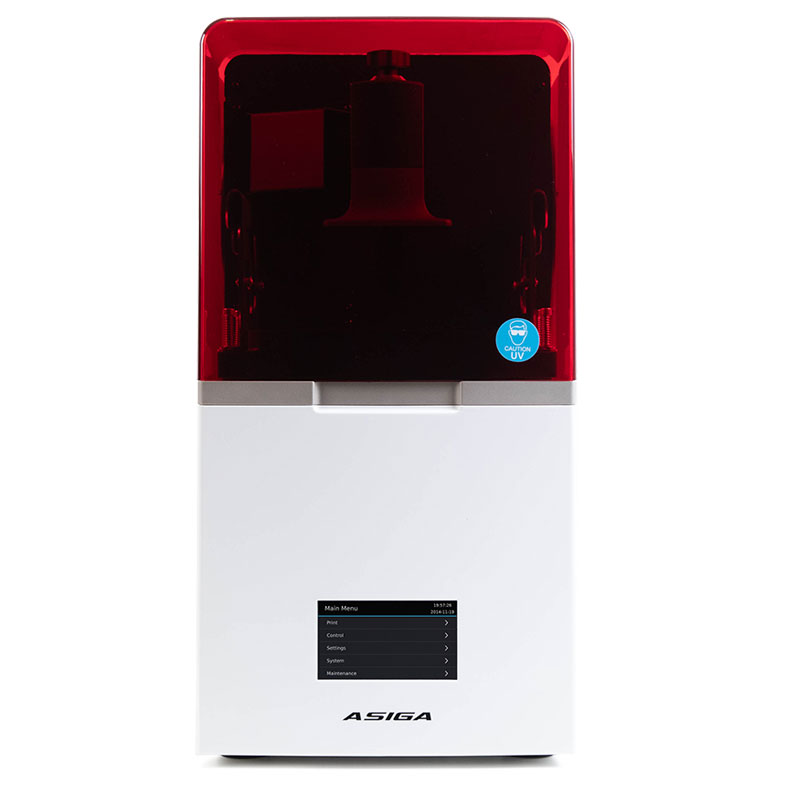

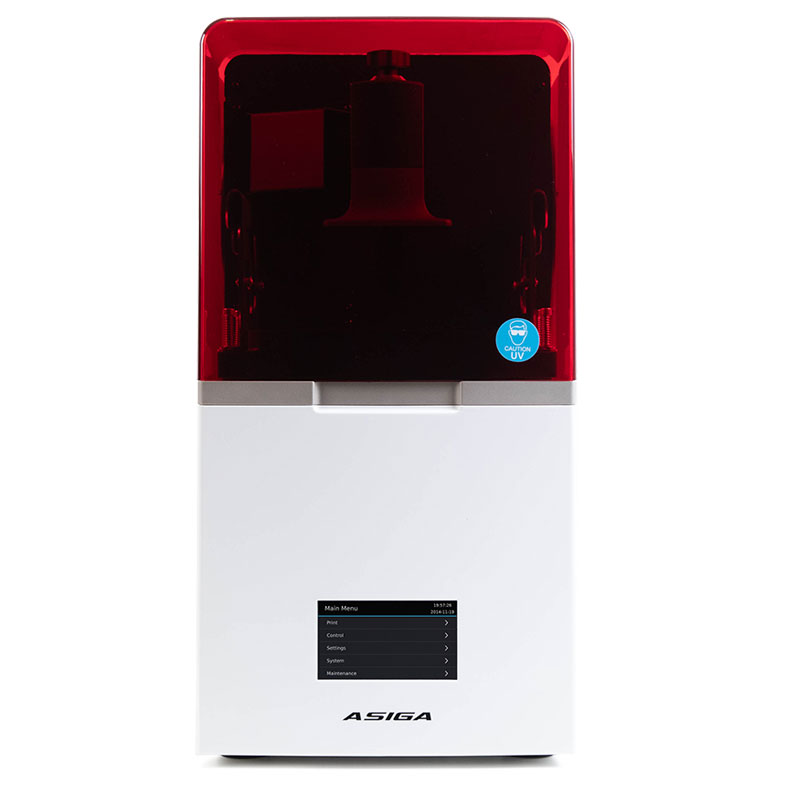

Asiga introduced affordable high-end 3D printing technologies to the jewellery industry back in 2011. In fact, it’s where our journey began.

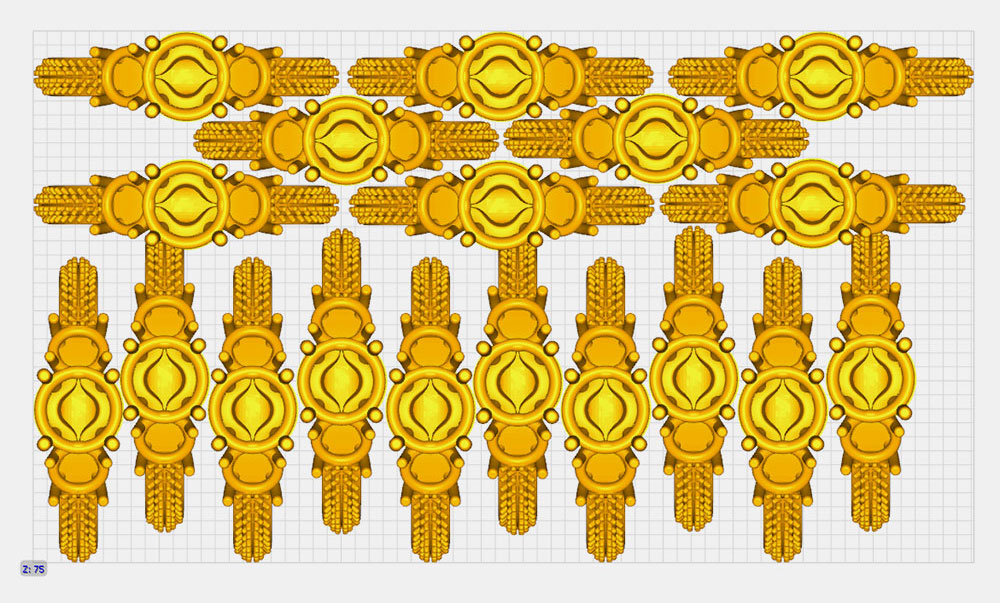

Exquisite detail.

A combination of small pixel sizes, our SPS™ technology for layer formation control and optimised material curing provides a level of detail and surface definition for the production of fine jewellery.

Enjoy access to all the leading jewellery printing materials as part of our Open Material Library to keep your business future-proofed. Blend your artisanal craft with digital repeatability and precision.

“We now have 3 Asiga MAX X printers across our stores as they continue to deliver exceptional results.”

Chris Eaton,

Solid Gold Diamonds

It all comes together at Palloys

Through the doors of Australia’s largest jewellery casting house.

Ash-free casting

With investment casting dating back thousands of years, we have spent well over a decade understanding and developing materials for the modern jeweller.

Investment casting is a crucial part of the jewellery manufacturing process and we have a wide variety of casting materials to choose from. Select a material compatible with gypsum and/or phosphate bonded investments and make a material selection that suits your individual casting requirements.

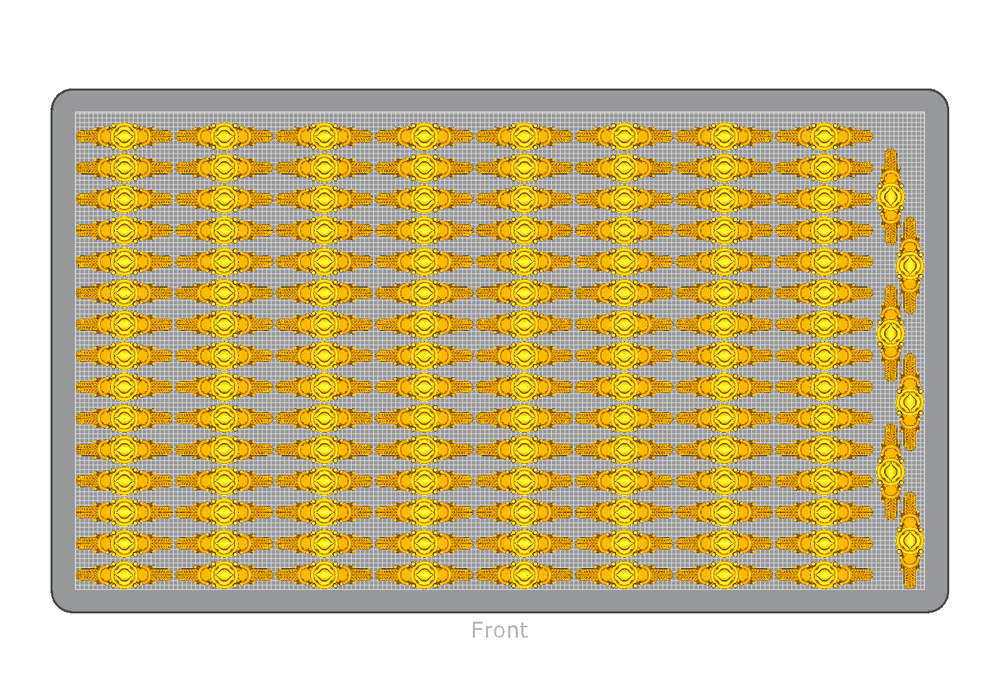

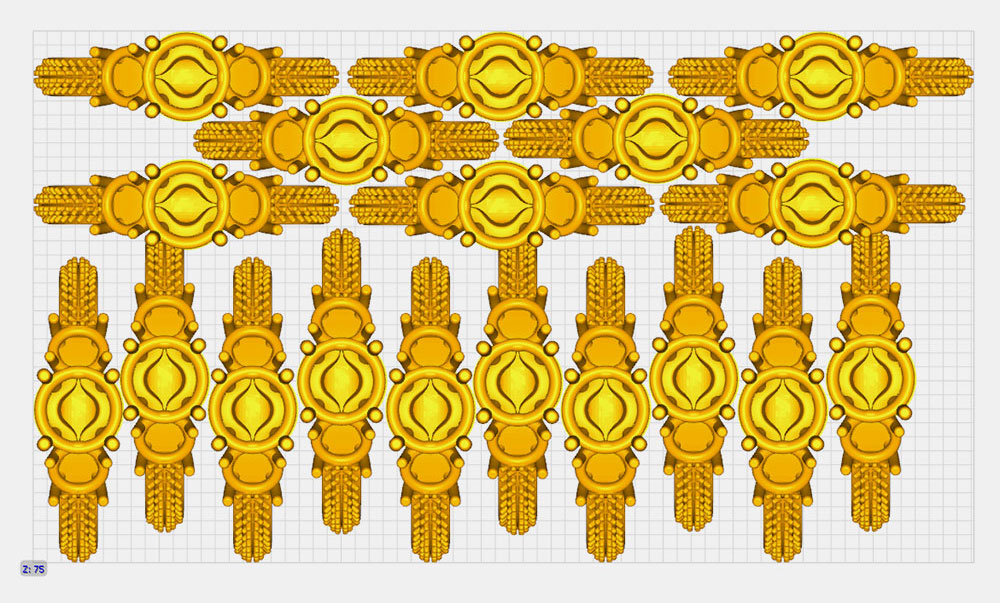

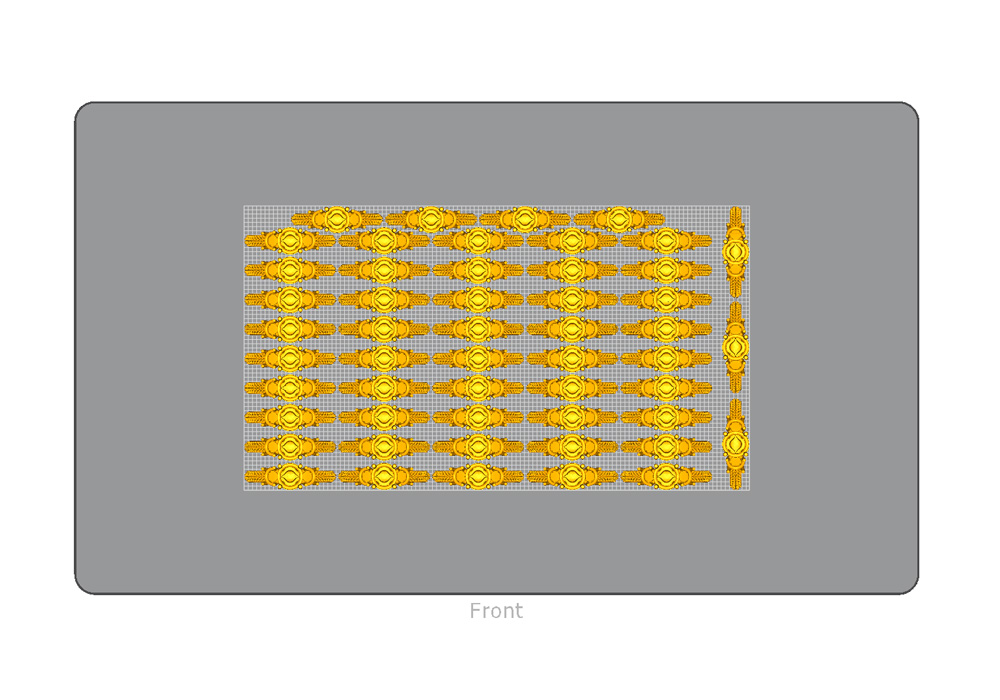

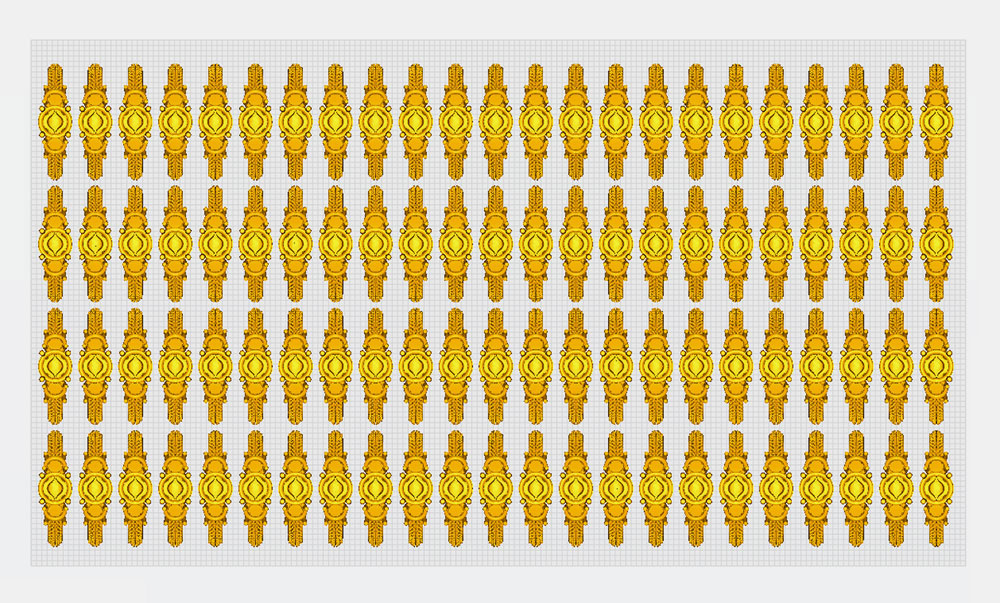

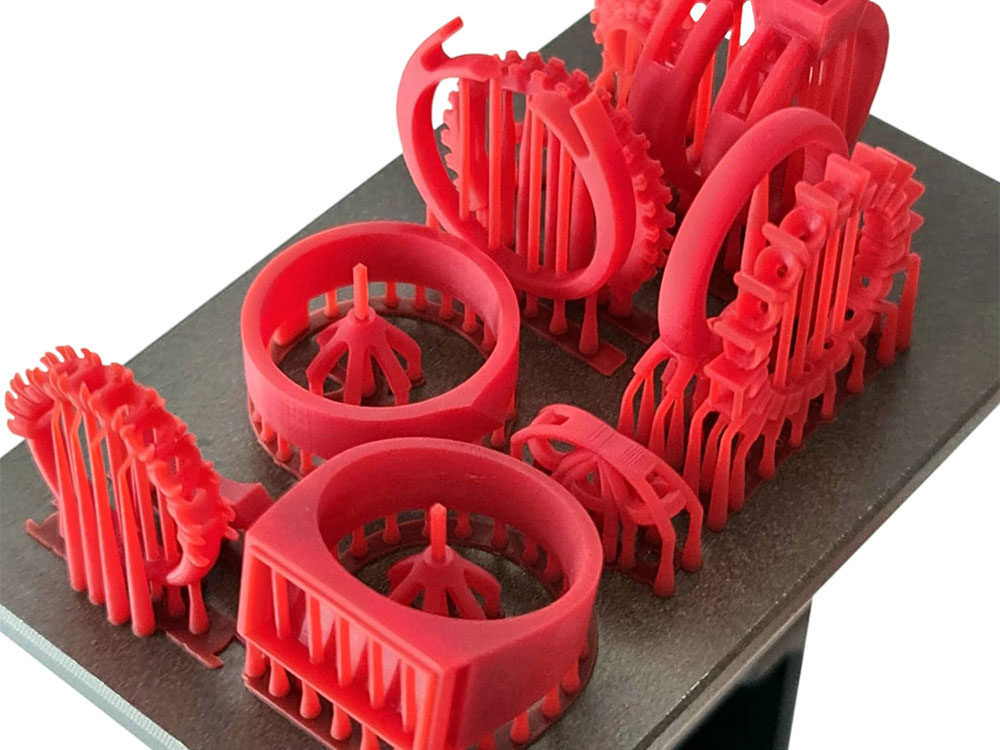

Powerful build set-up

Asiga Composer provides an effortless and automated build set-up process thanks to our auto-nesting and Lattice support structures.

Place support structures only where they need to be, protect the details that matter and peel away supports as easily as placing them in software.

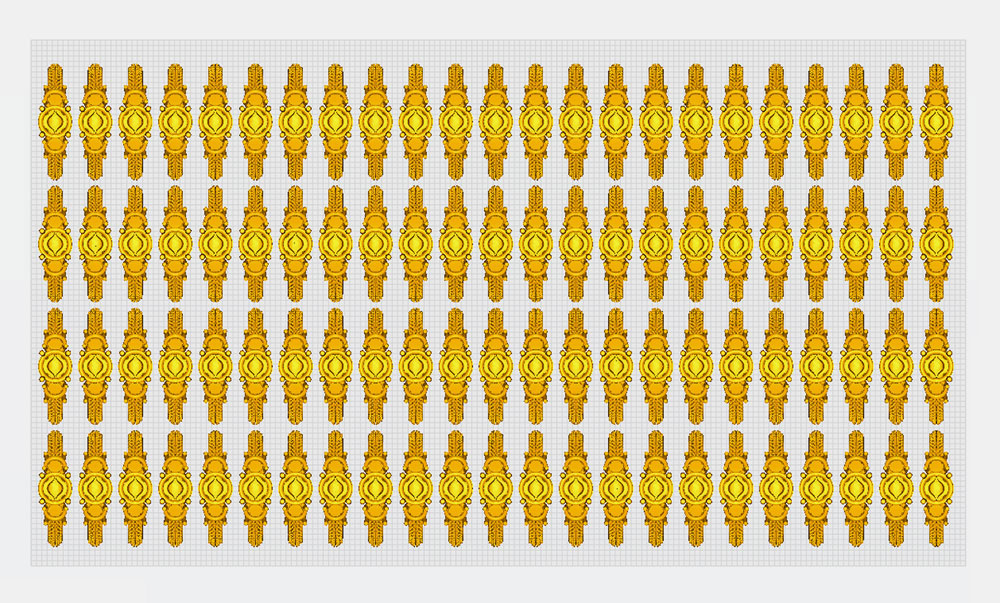

Low or High volume?

3D print in-store with the MAX X or activate high volume production on the PRO 4K65 UV. Selecting an Asiga 3D printer is easy. Choose the model that best suits your production volume requirements, see comparisons below:

MAX X

Low volume desktop production.

MAX X35 or

MAX X43

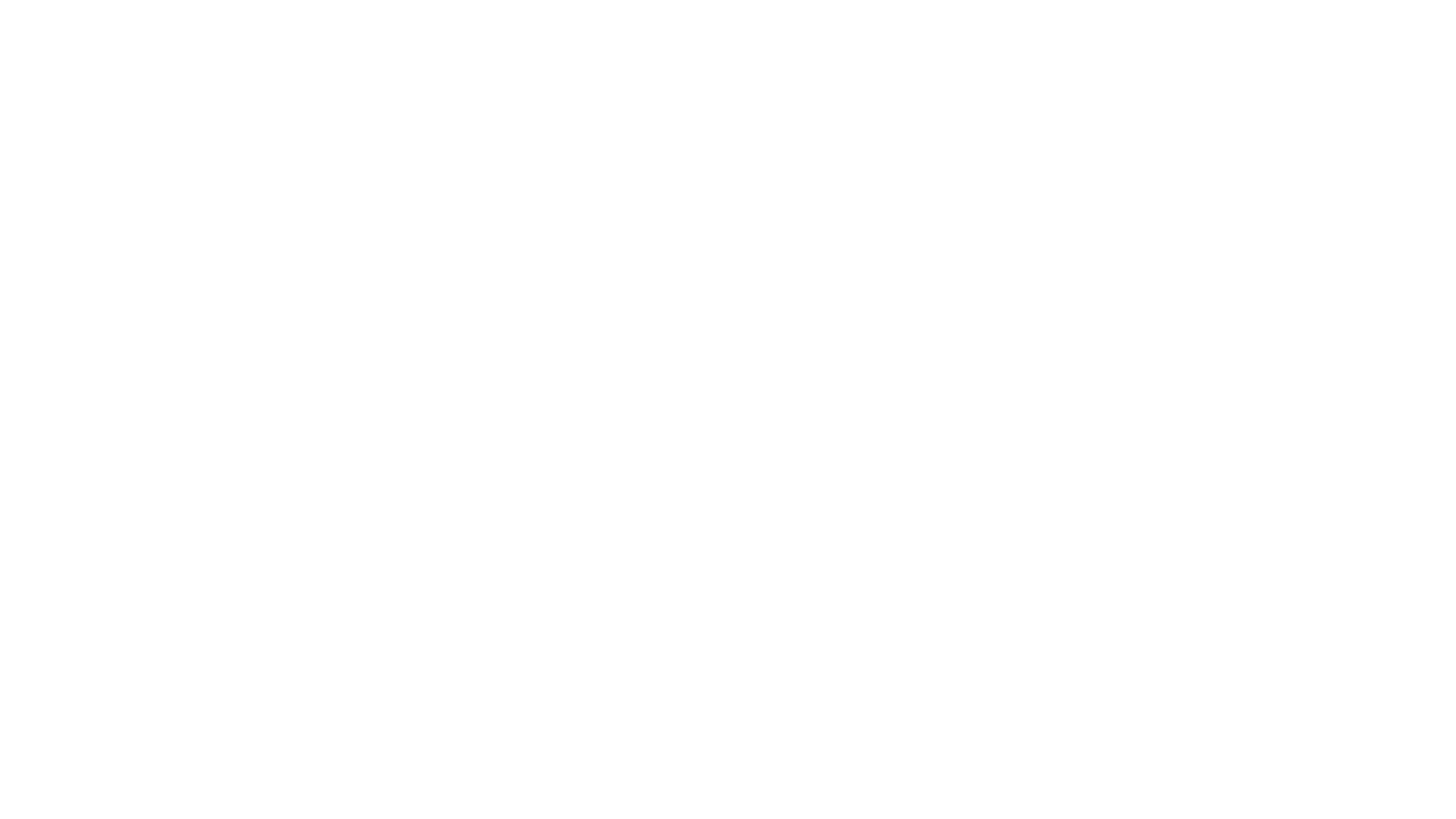

MAX X35 Output

Volume

18 rings

Print time

10mm/hr – 25 micron layers

MAX X43 Output

Volume

26 rings

Print time

10mm/hr – 25 micron layers

PRO 4K65

High volume jewellery production.

PRO 4K65 or

PRO 4K80?

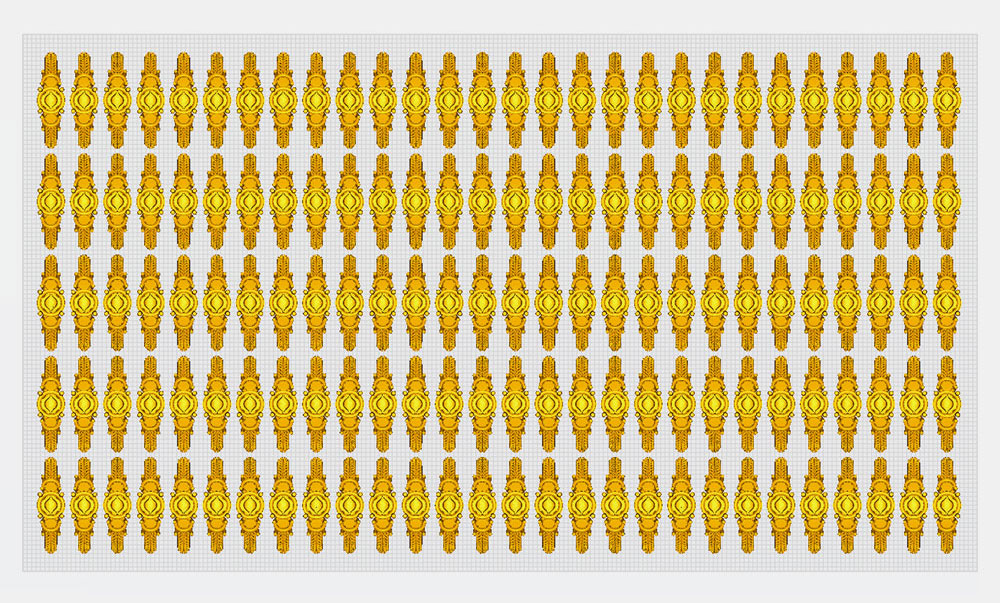

PRO 4K65 output

Volume

92 rings

Print time

10mm/hr – 25 micron layers

PRO 4K80 output

Volume

140 rings

Print time

10mm/hr – 25 micron layers

MAX X

Low volume desktop production.

MAX X35 or

MAX X43

MAX X35 Output

Volume

18 rings

Print time

10mm/hr – 25 micron layers

MAX X43 Output

Volume

26 rings

Print time

10mm/hr – 25 micron layers

Ultra

Built to outperform.

Ultra (32) or

Ultra (50)

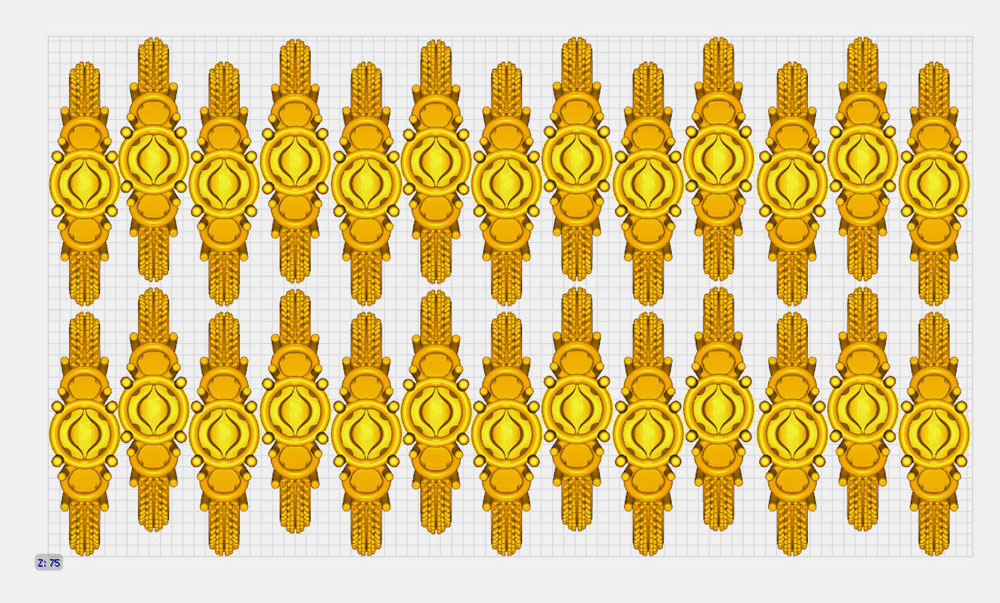

Ultra (32) Output

Volume

52 rings

Print time

10mm/hr – 25 micron layers

Ultra (50) Output

Volume

126 rings

Print time

10mm/hr – 25 micron layers

PRO 4K65

High volume jewellery production.

PRO 4K65 or

PRO 4K80?

PRO 4K65 output

Volume

92 rings

Print time

10mm/hr – 25 micron layers

PRO 4K80 output

Volume

140 rings

Print time

10mm/hr – 25 micron layers

3D printable wax

Investment casting made simple with Asiga SuperWAX.

SuperWAX is a 3D printable wax with exceptional burn-out characteristics in both gypsum and phosphate bonded investments. Ideal for those more familiar with casting injectable wax patterns.

Software compatibility

Seamless integration with leading jewellery design software.

Our 3D printers accept STL, PLY and SLC files for industry-wide compatibility with all leading jewellery design software providers.

Digital craftsmanship

Compliment your handmade artisan skills with digital manufacturing techniques.

Manufacture fine jewellery, time pieces, costume jewellery and master patterns for mould making, quickly and consistently.

Open Material Freedom

With more than 500 materials available at your finger-tips take control of your production output. Unlimited access to many of the world’s leading jewellery materials today, tomorrow and in the future.

Future-proof your business and stay up-to-date with the latest material developments from those who do it best. Optimised, validated, approved materials ready for ‘plug & play’ integration into your workflow.

Nobody does it better!

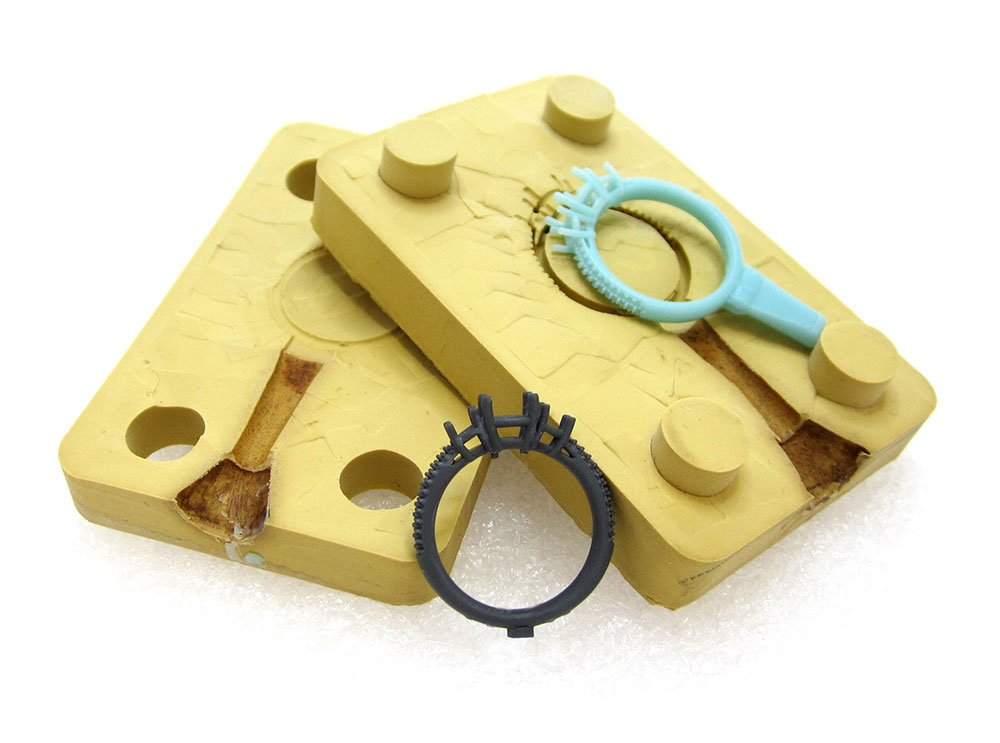

Production moulds or direct 3D printing?

The choice is yours.

Take advantage of a wide range of Asiga jewellery materials including our high temperature FusionGRAY for vulcanised rubber mould making. FusionGRAY provides exceptional detail definition, super smooth surfacing and is resistant up to 160 °C / 320 °F making it ideal for mould making.

Jewellery Resources

Visit our learning centre to see how our products are used in the jewellery industry.

3D printers for jewellery manufacturing

Contact us today to find out how Asiga 3D printers can enhance your digital capabilities.