Desy combine Asiga 3D Printers with Moiin Materials for microfluidic success

Deutsches Elektronen-Synchrotron DESY is the world’s leading research centre for accelerator, particle and astroparticle physics as well as for research into photon science. DESY scientists research the fundamental relationships between the structure and function of matter at the highest international level, creating the necessary knowledge basis to solve urgent social, scientific and economic questions. The accelerators as well as the detection instruments that DESY develops and builds are unique, highly sensitive tools. They make cutting-edge research and innovations possible.

DMG Digital Enterprises is a Hamburg-based manufacturer of 3D printing materials. DMG possesses specific specialised knowledge and has many years of experience in material development and 3D printing applications. The high-performance resins of the MOIIN brand developed by DMG are highly precise thanks to CDB technology – and have piqued the curiosity of DESY researchers.

3D printer manufacturer Asiga from Sydney, Australia is at the forefront of additive manufacturing technologies for the direct manufacture of end use products. Asiga 3D printers have been adopted globally across many precision industries including medical device manufacturing, science & research, jewellery and general additive manufacturing. Asiga 3D printers house a proprietary layering technique called their Smart-Positioning-System (SPS™) Technology which ensures the precise formation of each layer resulting in production reliability and continuity. Asiga’s Open Material System also provide compatibility with many of the world’s leading materials developers including DMG / MOIIN.

For DESY the 3D printed output needed to achieve a number of key requirements. Ultra-precision to capture miniature capillaries with an internal diameter of approximately 1 mm and a wall thickness of only 100-200 µm. These intricately 3D printed capillaries were produced on the ‘Asiga MAX X27 UV’ in MOIIN materials for one of DESY’s current projects ‘Acceleration and deflect of electron beams with terahertz radiation’. Strength of the material and stiffness of the capillary were essential and also the reduction of absorption losses of the THz rays in the 3D printed material. Another requirement was for the MCIIN material to be used as in an ultra-high vacuum environment.

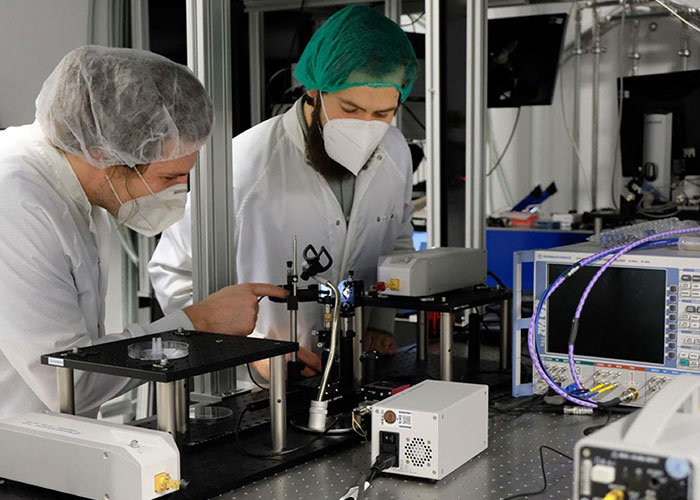

To date the DESY team has worked with 3D print material ‘MOIIN Tech Clear’ to achieve high accuracy and detail for the complex geometries required. Excellent results were achieved with the ‘Asiga MAX X27 UV’ 3D printer. This material / 3D printer combination was the first to be tested by DESY scientists and initial tests show promising printing results. “We need reliable materials for extremely detailed structures, which need to withstand extreme conditions – such as ultra-high vacuum, which we need for beam manipulation, radiation generation and diagnostics,” explains Frangois Lemery, DESY-researcher in the accelerator division who is heading the project. He continues: “Max Kellermeier, our Ph.D candidate, has been driving the characterization of the printed samples using laser-based measurement methodology and vector network analyzers to obtain a complete picture of the material properties in the THz range. The results are very promising to further integrate 3D printed plastics for novel future accelerator applications.”

Enhanced materials for 3D printing, developed by this cooperation between DESY and DMG, will not only benefit multiple projects in the scientific field, but can spur innovation in a wide range of applications for 3D printing with high throughput and stringent quality requirements.

For more information visit:

Deutsches Elektronen-Synchrotron DESY

Website: innovation.desy.de

MOIIN / DMG Digital Enterprises

Website: moiin-resins.com

Share: