A game changer for chairside splint production.

Case study by Dr. Kasen Somana, Signature Dentistry

3D printed Miniatures. Yes, they are really that small!

Through the doors of Aetherworks and Victoria Miniatures to see how they have embraced digital manufacturing.

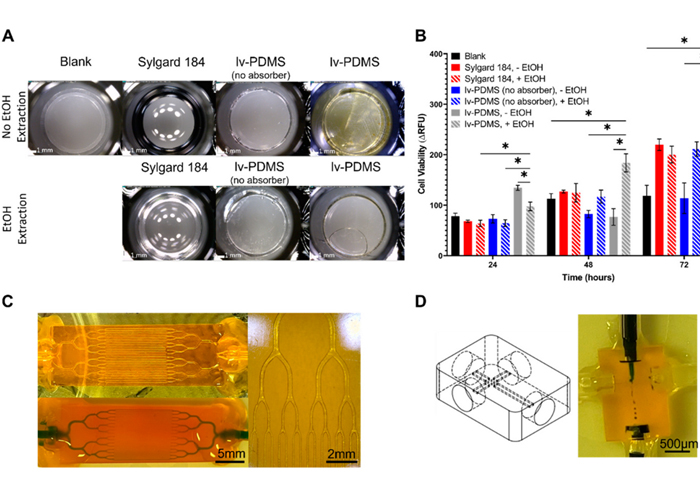

Low-Viscosity Polydimethylsiloxane Resin for Facile 3D Printing of Elastomeric Microfluidics

This paper presents a high-resolution, PDMS 3D-printing resin for the facile fabrication of microfluidic and biomedical devices.

Asiga biocompatible materials now listed with the FDA and available for use in the US

DentaGUIDE, DentaTRY, DentaTRAY and DentaIBT

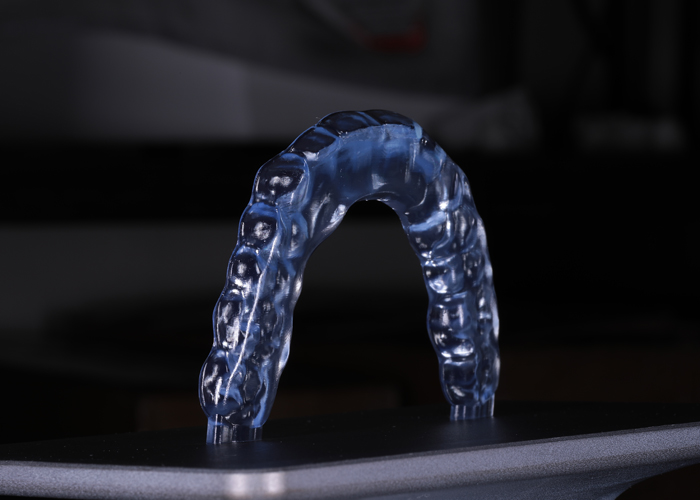

A new era of splint production has arrived.

Written by Matthias Zimmerer, Application Engineer, CDT, certified exocad trainer, Schütz Dental 3D printing is quite possibly the main manufacturing process used for splints today. 3D printed splint materials are tough with some being hard & rigid and others softer with a memory for patient compliance and comfort. The output will vary from printer to […]

UltraGLOSS™, polished parts direct from the 3D printer.

No more manual

Asiga at LMT® LAB DAY® in Chicago

23-25 Feb 2023, Hyatt Regency Chicago, USA

3D printing at Cordent

Asiga at one of the largest dental laboratories in the Netherlands.

Additive manufacturing saves time & cost for ASSA ABLOY

ASSA ABLOY were looking for a tough material that offers long-term durability, could withstand 120,000 cycles and maintain an excellent surface finish.

Enhancing the exploration of our galaxy and beyond with the small but effective Starbug robots.

Developed by the Australian Astronomical Optics (AAO), Starbug’s are tiny, legless, armless fibre optic positioning robots working on some of the world’s largest telescopes.