The Future of Dental Simulation.

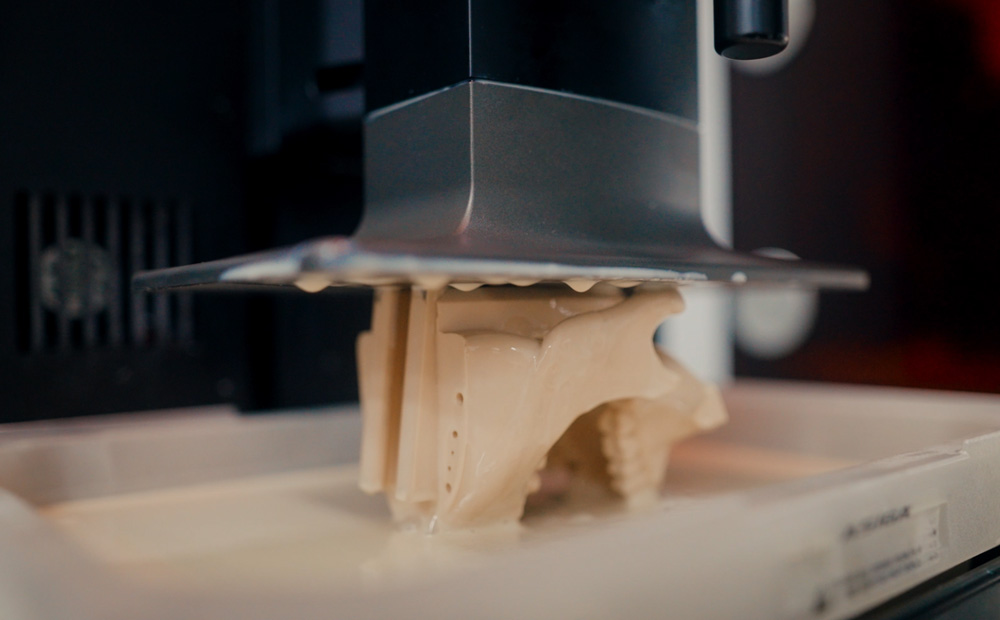

Meet Tina4D. A true anatomical replica of a real-life Tina.

Anatomic4D, based in Sydney, Australia develops and manufactures advanced 3D printed ‘True to Life’, ultra-realistic dental simulation products for education and training of dental practitioners

3D printing has revolutionised clinical workflows and outcomes for dentists and patients in dental offices across the world, however, the needle has barely moved in the simulation space.

Dental education and training is still reliant on expensive injection moulded Typodont models and manikins that have barely changed since they were first introduced to dentistry over a hundred years ago.

Typodonts are typically manufactured with perfect rows of plastic teeth and an idealised occlusion. Although they may look like teeth, they simply aren’t comparable to natural human anatomy which limits learning outcomes and offers little in the way of realism.

A New Type of Virtual Reality - Replicating Life Itself.

Anatomic4D saw a genuine unmet need and opportunity for developing a brand new class of simulation models to deliver immersive training in restorative, surgical, endodontic and implant dentistry.

Accurately replicating the structure, density and fine internal anatomy of human bone, jaws, teeth and root canals creates complex challenges and need for new manufacturing processes.

As a starting point, we selected ‘Tina’ as the patient to replicate. Unlike the plastic typodont, Tina’s teeth aren’t perfect. She is a typical dental patient and the perfect simulation model. Using Tina’s intra-oral 3D scans and cone beam x-rays, we were able to meticulously re-create her jaws and anatomy at a 1:1 scale.

We digitised Tina and created Tina4D. Tina4D models are a true anatomical replica of the real Tina down to her jaws, bones, teeth, roots, supporting periodontal ligaments, pulp chambers and root canals. A paradigm shift in simulation models.

“Our anatomic models are extremely complex requiring very low micron accuracy. When it came 3D printing, we exclusively used the Asiga Max UV and Pro 4K printers and resins which enabled us to carry out rapid prototyping to the level of accuracy we needed to replicate Tina’s anatomy. There was simply nothing in dentistry that we found that came close to the Asiga for delivering precision and detail that our true to life models required.”

Dr Rakesh Jivan, Clinical Director, Anatomic4D

The precision of the Asiga PRO 4K and MAX UV and Asiga dental materials provided a platform for us to produce unbelievably smooth to the touch models that look striking, and feel real. This level of production quality and consistency with Asiga enabled us to utilise 3D printing to manufacture Tina4D.

The Tina4D range of simulation models deliver an accurate life-like tactile feeling experienced by dentists during extractions, root canal treatments, implant placement and restoration of teeth.

The Anatomic4D journey into replicating life with Asiga printing technology has only just scratched the surface of possibilities. We have the ability to recreate any living patient and deliver an unparalleled immersive learning experience.

Our in-house R&D coupled with Asiga’s technology has already positively impacted the way in which current and future dental students and dental practitioners learn and train.

Through our technological breakthrough, the Tina4D head, replaceable jaws and integrated bench top clamp system enables education providers and individual dental practitioners to set up simulation clinics in any location worldwide. By using Asiga 3D printers and Asiga materials, we have simultaneously reduced the burden cost of delivering training and eliminated the need for bulky and expensive manikins.

For more information on the Asiga MAX UV click here >

For more information on the Asiga PRO 4K click here >

For more information on Anatomic4D click here >

Share: