UltraGLOSS™ 3D printed hearing aids.

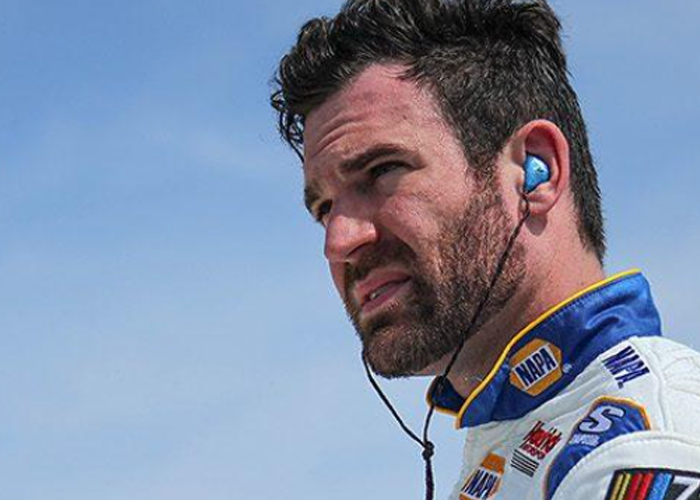

Written by Adam Wojciechowski, Senior Production Engineer, Demant

The possibility of conquering the sky had always been one of the eternal dreams of mankind. Most of us are aware of the spectacular technological achievement when Neil Armstrong took his first step on the moon back in 1969.

“That’s one small step for a man, a giant leap for mankind”.

The introduction of the innovative UltraGLOSS trays for our 3D printing process was a similar achievement in the microcosm of Demant Custom Production Department. Does that all sound a little excessive?

Well, maybe for some but please take a few minutes to read my story.

Hearing Aids production can be divided into two basic styles:

BTE - Behind-the-ear

ITE - In-the-ear

ITE hearing aids are almost entirely produced using additive manufacturing technology and have been for more than 30 years.

Yes!! In the hearing sector 3D printing has been an integral manufacturing process used to manufacture the end-use patient matched hearing aid.

The process starts with an impression from the patients ear, this is then 3D scanned to capture the geometry in a digital format. This scan is then manipulated in custom hearing design software to create an earshell or earmould to best suit the patients needs. The ITE earshell is then 3D printed in a biocompatible material, post finished and then all our miniaturised electronics are assembled into the 3D printed shell. A base plate is bonded to the shell to pot the electronics and the device progresses for testing and tuning.

3D printing or additive manufacturing is essential to create this patient matched device to ensure the highest level of comfort and enhanced audio capabilities.

Our daily production demand is in excess of 1000 pieces so to achieve success, the key is to optimize 3D printing and post processing while maintaining the highest level of product quality achievable.

Demant have been at the forefront of hearing technology and manufacturing techniques for decades and always on the look out for manufacturing efficiencies. Many times my colleagues push to see where we can optimise the 3D printing process and to reduce polishing. Polishing of an earshell is probably the most labour intensive step in the process to improving surface finish while maintaining printing speed to meet demand are always a common driver.

Manual polishing

While manual polishing is one solution we must remember that it is not that straight forward. A manual or automated polishing process removes material from the earshell and thus affects many aspects including patient fit, comfort and effectiveness of the hearing instrument.

It is an ongoing project to see how we can optimise the production process and achieve an excellent surface finish in the least amount of time & labour.

We have undergone countless tests and processes, consuming huge amounts of materials and resources to settle on a manufacturing process that really was as good as it was going to get. Well, we thought so.

Then, something changed.

When it seemed that we had tested everything, in came the UltraGLOSS trays from Asiga.

Now, I will admit. I was sceptical at first. With almost a decade of experience in additive manufacturing for hearing production ‘and’ endless searching for solutions to enhance and improve our process I thought we had tested everything.

To my amazement, the first earshell we printed was exactly what we were dreaming to achieve.

This could not be true. All you need to do is replace a standard tray with an UltraGLOSS tray and you start printing with a glossy finish straight out of the printer..? Really?

Yes, it was that simple.

The comparison test

For supply chain stability we always select two or more manufacturers for each stage of our manufacturing processes. With this in mind we decided to run a comparison study to evaluate (under a microscope) the results from an Asiga printer using UltraGLOSS and another printer using their standard tray. The same material was used.

Test #1

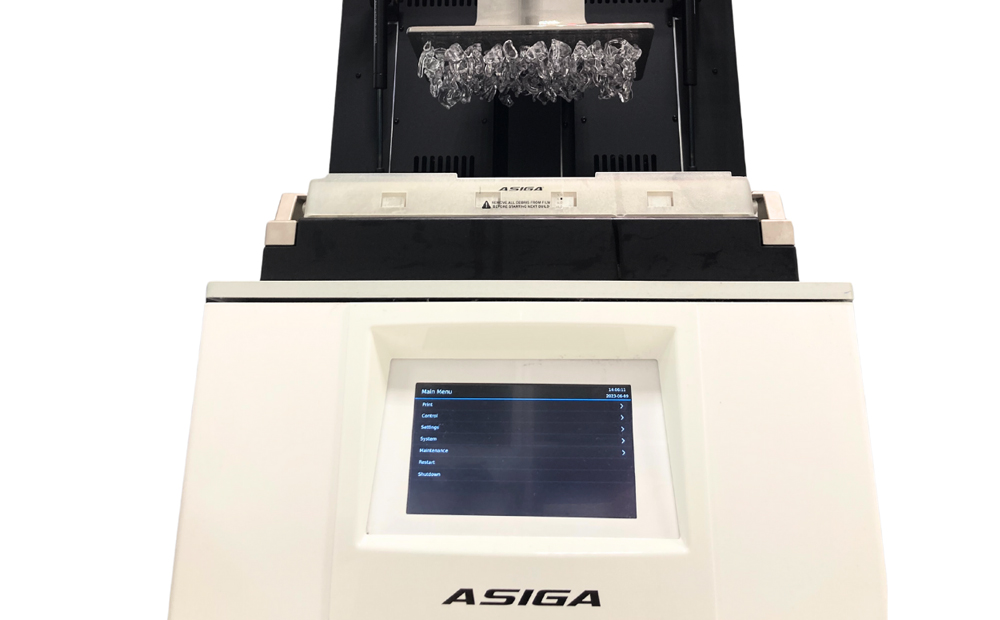

3D printer – Asiga 3D printer

Material – Detax Medical Print Beige 2.0

Tray – UltraGLOSS

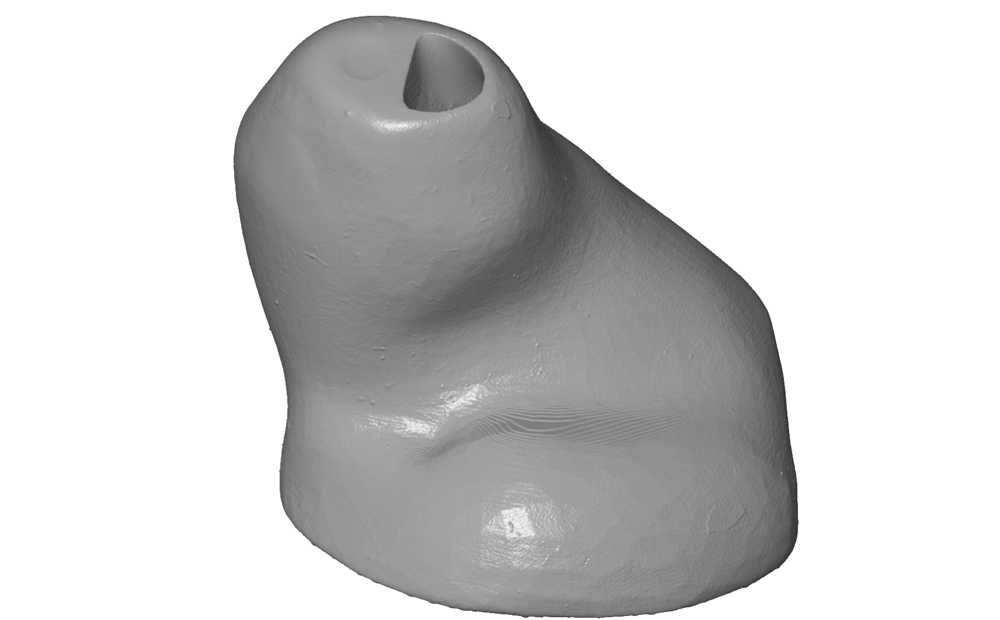

Image taken from scan of 3D printed earshell, printed using the specification above.

Test #2

3D printer – other manufacturer printer

Material – Detax Medical Print Beige 2.0

Tray – other manufacturers own tray

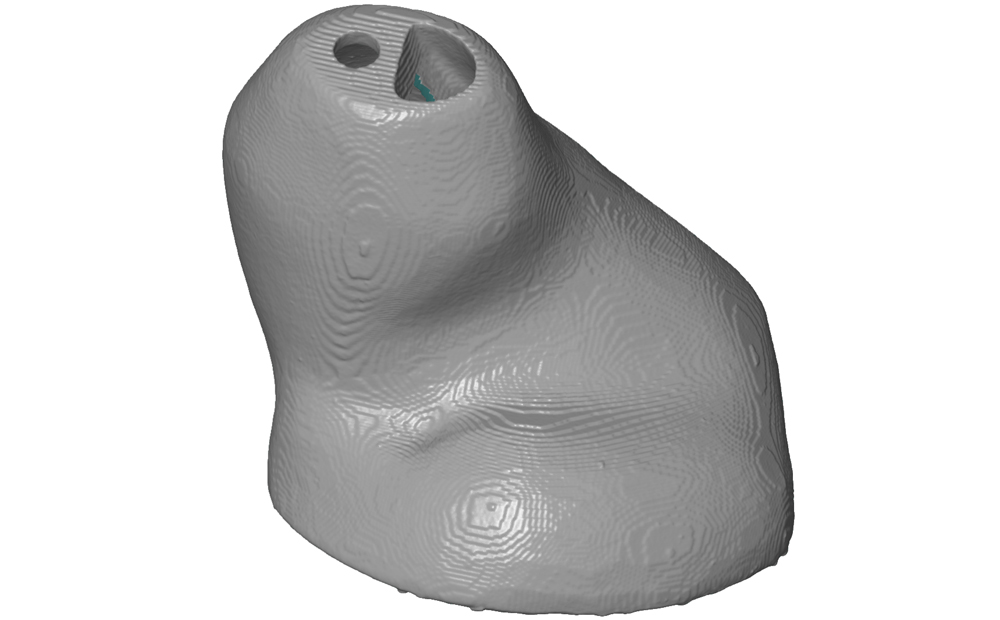

Image taken from scan of 3D printed earshell, printed using the specification above.

The result

The difference was clear. The Asiga printer using the UltraGLOSS tray resulted in a super-smooth surface finish. Very minimal post finishing was required making it an ideal solution for our production.

Below is a comparison showing the finished results using a clear audio resin. This time we used the Asiga printer for both tests and printed the same earshell on the UltraGLOSS tray (left) and also the Asiga Low Force tray (right).

Manufacturing implementation

UltraGLOSS has had such an incredible impact of the 3D printed surface quality helping us optimise post-processing, reduce production time frames and enable us to deliver product to our customers faster than ever before. We are saving several hours each day in our automated post-polishing area.

We believe that the UltraGLOSS tray from Asiga is a game changer for earmould and earshell production. So, my words at the start of this were not entirely unfounded.

UltraGLOSS is now an integral part of our manufacturing process here at Demant.

About Adam Wojciechowski

Senior Production Engineer, Demant Operations Poland Sp. z o.o. Custom Production Department.

Adam has nearly 15 years experience working in an environment of high-volume technology production. The first career steps taken at Intel microchips and Hewlett-Packard inkjet printers production. For almost 10 years associated with Additive Manufacturing Technology in Hearing Aid Industry. Responsible for Engineering Supervision of 3D printing process in DLP technology on Custom Production Department.

Share: